The basics of metro train running

are same as the running of main

line trains. The metro trains

need quick acceleration and the interstation

distances are small. Also the

new metro trains are provided with 3-

phase induction motors and the gear

ratio used for the metro trains are

very high.

The metro trains are for the use of

the city dwellers. The commuters

should take as little time to reach

their place of work and return home

in the least possible time. The

commuters do not carry heavy

luggage with them like the long

distance travelers. The toilet

facilities are provided only on the

platform. The doors of the metro

trains are closed while it is running.

These are some of the features of

metro trains.

ACCELERATION

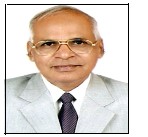

As can be seen from Fig 1, out of the

total torque, part is utilized to

overcome the load torque and

balance is available for accelerating

the motor. If the surplus torque is

more, the motor accelerates quickly.

The motor attains a balancing speed

at A when the load torque and the

motor torque are equal. Since at

point A, no surplus torque is

available, the motor will run with a

speed corresponding to slip S1.

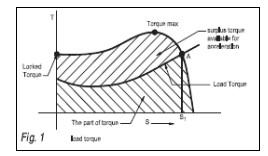

For the vvvf drive, the points on

family of torque slip curves are joined

to get a form given as A B and C in the

Fig 2 given below.

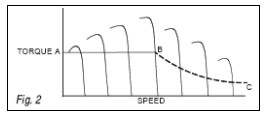

In Fig 3, A B is a constant torque

region and BC is a constant power

region. Though for the vvvf drive

motor, it is a common practice to

show the curve AB & BC as given

below, it should be kept in mind, that

the vvvf drive motor is an induction

motor and behaves like a normal

induction motor.

In Fig 3, when a chosen frequency

corresponds with synchronous speed

for point R, the, motor will develop a

torque corresponding to point Q. If

the frequency is increased further, the

speed will increase till it reaches point

T. The speed corresponding to point B is

the base speed and the corresponding

frequency is the base frequency. The

motor will operate most efficiently at

the point B and the motor is designed to

work at this point. BC region is like a

weak field region of dc series motor.

The speed in this region is above the

normal speed and the torque is reduced

and follows a curve BC.

It will be clear from the figure that

after point B, the accelerating or

surplus torque gets progressively

reduced. The rate of acceleration

therefore reduces.

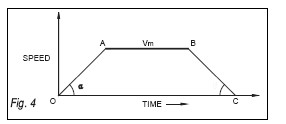

The speed with dc motor will increase

along line oA and remain stable from

point A to B after B it gets reduced due

to braking till it reaches point C. This is

the speed time curve with dc motor.

The acceleration and retardation are

tan a and tan ß respectively. This graph

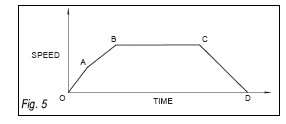

gets slightly modified in vvvf control

(Fig 5).

The oA corresponds to the

accelerations in constant torque region,

followed by AB in constant power

region. The rest of the curve is same as

in Fig 4. But normally instead of using

two accelerations, average acceleration

is used and a Fig 4 is used for the

calculations of various parameters in

practice even for vvvf drive.

The use of high power motor is

preferred by many people for achieving

the quick acceleration. But, the use of

optimum size of the motor should be

made to ensure minimum loss of power.

Copper loss is thus proportional to the

square of the voltage applied. Use of

high acceleration will mean use of high

P2 or high V in V/ƒ ratio.

Aiming to achieve high speed in quick

time will result into high loss of energy.

We therefore need to see whether

achieving high acceleration is necessary

to obtain the minimum possible interstation

running time.

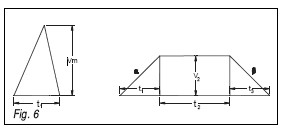

Consider the two speed time curves

given in Fig 6.

It is possible to construct the triangle

and the trapezium of the same area,

which would be the interstation

distance. If the maximum speed Vm is

high, the altitude of the triangle will be

high. The base of the triangle will be

therefore less. In the second case, the

base is more and the height of the

trapezium is less. Thus, with an

acceptable running time between the

stations, the, altitude of the trapezium

can be reduced, thereby reducing the

energy loss.

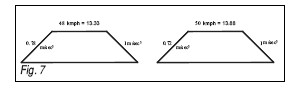

Consider a practical case of one of the

metro lines. The maximum speed is 80

kmph, the acceleration is 0.78 m/sec2

and the braking is 1 m/sec2. The

interstation distances are

approximately 1 km. The smallest

interstation distance is 596m and the

maximum is 1,432m.

The speed time curve for these two

locations is given in Fig 7

Thus it will be seen that it will not be

possible to attain a speed of 80 kmph.

The traction motor does not touch the

knee point but stops short of it. The

traction motor runs efficiently at fb &

vb, the base frequency and base voltage.

At the lower speeds, the motor will

operate at high slips and hence, will

result into greater loss. It is therefore,

desirable to have motor of proper rating

to ensure minimum loss. If a bigger size

of the motor is selected, apart from the

motor running inefficiently, the size of

the transformer in the motor coach will

be more and also the size of the traction

transformer in the substation will be

more. This too will result into more

loss. The metro systems, if motor size is

not properly selected, it will result into

loss of energy and will ultimately lead to

leakage of revenue.

USE OF HIGH GEAR RATIO

The high gear ratio will result into

higher acceleration as the torque will

increase at the cost of the speed. This is

advantageous at start but the balancing

speed is achieved at higher value of

voltage in the V/ƒ ratio. Since the

copper loss will go up with higher

voltage, the use of optimum gear ratio

will minimize the loss of energy.

Conclusion: There is a tendency to use

bigger size of traction motors for quick

acceleration. Similarly to increase the

starting torque, higher gear ratios are

employed. There is a limit to which

higher sizes can help. The use of bigger

size of the motor results into higher

capital and running costs of metro

trains. Therefore, the traction motor

and a gear ratio of correct size should be

chosen for the metro applications.

(S.P. Khade is Director-Technical,

Mumbai Metropolitan Region

Development Authority)