India is making slow

but steady progress

in its endeavour of

adding thermal power

capacity using

supercritical

technology. India's

inherent dependence

on coal-fired power

plants cannot be

wished away and

deploying this

efficient technology is

a viable means to

mitigate the carbon

footprint.

Venugopal Pillai

takes a look at recent

developments in the

supercritical power

equipment business.

India made a modest beginning in deploying

supercritical technology way back in 2004 but it is

only in the past two years that there is visible progress.

India's objectives are twofold. First, the country needs

to expeditiously set up supercritical power plants with a

view to ensuring efficiency in power generation, and

second, it needs to create a local base for equipment and

services in the field supercritical power plants. Today, there

is considerable progress on the first count, and on the

second, a sound beginning has been made.

According to a special study by Electrical Monitor, orders

for supercritical power equipment (boilers and turbinegenerators)

aggregating around 51,500 mw were placed by

Indian power producers, as of mid-March 2012. Another

12,000 mw of orders are on the verge of finalisation. (See

Section NTPC's mega tender.) An important point to note

is that Chinese suppliers are currently playing a very

dominant role. However, as we move in time, a domestic

manufacturing base will emerge as a formidable force—the

incipient signs of which are conspicuous today.

SUPERCRITICAL POWER PROJECTS AWARDED* |

| Developer |

Project |

Capacity (mw) |

Boiler |

Turbine-Generator |

| |

|

Units |

Total |

|

|

| Public Sector and JVs |

| APGenco+IL&FS |

Krishnapatnam, Andhra Pradesh |

2x800 |

1,600 |

Bharat Heavy Electricals |

L&T-MHI |

| Karnataka Power Corporation |

Bellary, Karnataka |

1x700 |

700 |

Bharat Heavy Electricals |

Bharat Heavy Electricals |

| KPCL+BHEL |

Raichur, Karnataka |

2x800 |

1,600 |

Bharat Heavy Electricals |

Bharat Heavy Electricals |

| Mahagenco |

Koradi, Maharashtra |

3x660 |

1,980 |

L&T-MHI |

L&T-MHI |

| NTPC |

Sipat (Stage 1), Chhattisgarh |

3x660 |

1,980 |

Doosan Heavy Inds, Korea |

OJSC Power Machines Group, Russia |

| NTPC |

Barh (Stage 1), Bihar |

3x660 |

1,980 |

Technoprom Export, Russia |

OJSC Power Machines Group, Russia |

| NTPC |

Barh (Stage 2), Bihar |

2x660 |

1,320 |

Bharat Heavy Electricals |

Bharat Heavy Electricals |

| NTPC |

Kudgi, Karnataka |

3x800 |

2,400 |

Doosan Heavy Inds, Korea |

Toshiba-JSW |

| TNEB+BHEL |

Udangadi, Tamil Nadu |

2x800 |

1,600 |

Bharat Heavy Electricals |

Bharat Heavy Electricals |

| Private Sector |

| Adani Power |

Mundra, Gujarat (Unit 5 - 9) |

5x660 |

3,300 |

Harbin, China |

SEPCO III, China |

| Adani Power |

Tirora, Maharashtra (Unit 1 - 3) |

3x660 |

1,980 |

Babcock, China |

BSTG, China |

| CLP India |

Jhajjar, Haryana |

2x660 |

1,320 |

SEPCO III, China |

SEPCO III, China |

| Dainik Bhaskar Power |

Singrauli, Madhya Pradesh |

2x660 |

1,320 |

Bharat Heavy Electricals |

Bharat Heavy Electricals |

| Essar Power |

Salaya (Phase II), Gujarat |

2x660 |

1,320 |

Harbin, China |

Toshiba Corporation, Japan |

| Jaypee Associates |

Nigrie, Madhya Pradesh |

2x660 |

1,320 |

L&T-MHI |

L&T-MHI |

| Jaypee Associates |

Prayagraj, Uttar Pradesh |

3x660 |

1,980 |

Bharat Heavy Electricals |

Bharat Heavy Electricals |

| Lanco Infratech |

Babandh, Orissa |

2x660 |

1,320 |

Dongfang Electric, China |

Dongfang Electric, China |

| Lanco Infratech |

Amarkantak (U3 & U4), Chhattisgarh |

2x660 |

1,320 |

Dongfang Electric, China |

Dongfang Electric, China |

| Lanco Infratech |

Mahanadi, Maharashtra |

2x660 |

1,320 |

Dongfang Electric, China |

Dongfang Electric, China |

| Reliance Power |

Sasan UMPP, Madhya Pradesh |

6x660 |

3,960 |

Shanghai Electric, China |

Shanghai Electric, China |

| Reliance Power |

Krishnapatnam UMPP, AP |

6x660 |

3,960 |

Shanghai Electric, China |

Shanghai Electric, China |

| Reliance Power |

Chitrangi, Madhya Pradesh |

6x660 |

3,960 |

Shanghai Electric, China |

Shanghai Electric, China |

| Reliance Power |

Tilaiya UMPP, Jharkhand** |

6x660 |

3,960 |

Shanghai Electric, China |

Shanghai Electric, China |

| Tata Power |

Mundra UMPP, Gujarat |

5x800 |

4,000 |

Doosan Heavy Inds, Korea |

Toshiba Corporation, Japan |

| Total |

|

|

51,500 |

|

|

| *As of March 23, 2012. List may not be exhaustive. |

A. FOREIGN SUPPLIERS

Role of China: The role of China in India's supercritical

equipment business has been profound. China has landed

orders aggregating over 27,000 mw that represents nearly

half the total orders placed by Indian power producers so far.

Shanghai Electric has been a very dominant name thanks

to its co-operation agreement with Reliance Power (Anil

Ambani Group). In October 2010, Reliance ADA Group

entered into a mega $8.3-billion agreement with Shanghai

Electric to supply 36 supercritical power units. The two

entities also agreed to co-operate on a host of other matters

in the power sector. Shanghai Electric Group has won

orders for equipment (boilers and turbine-generators) for

17,160 mw worth of supercritical power capacity.

Dongfang Electric of China has been a favourite for the

Lanco group that has placed orders for six

sets of 660-mw units. Unconfirmed reports

suggest that Lanco has also planned to

source subcritical and supercritical

equipment from Harbin of China. No

confirmation to this effect was

immediately available.

Other Chinese suppliers catering to the

Indian supercritical power equipment

market include SEPCO III, Harbin, BSTG

and Babcock China. Apart from Reliance

(ADA) Group, Chinese suppliers have

found favour with other private power producers like Adani, Essar and CLP India. In fact, none of

orders won by Chinese suppliers for supercritical power

equipment has been from the government sector—either

Central or state. It is expected that private power

producers will continue to order Chinese equipment, more

because there is no immediate alternative. Once domestic

equipment capacity gets built, the situation might

change. In the medium term though, there is no sign of

Chinese dominance easing off. It may also be mentioned

that the local manufacturing industry had demand higher

duty on import power generation equipment mainly to

thwart Chinese competition. However, this demand has

not yet been acceded to. In the foreseeable future,

therefore, China has very little competition.

Role of other foreign suppliers: Going forward, the role

of foreign suppliers (except Chinese) would be through joint

ventures forged with Indian companies. However, foreign

suppliers, in individual capacity, have won orders placed in

the past. For instance, the very first orders for supercritical

equipment were placed by NTPC on two foreign suppliers

like Technopromexport and OSJC Power Machines Group

(both from Russia) and Doosan Heavy Industries from

Korea. The Russian suppliers mentioned haven't had any

success after that, but Doosan Heavy Industries did receive

some orders—from Tata Power for the Mundra UMPP and

more recently from NTPC for the Kudgi project. For Both

these projects, Doosan is mandated to supply the 800 mwrated

boilers. Since Doosan is planning to set up a local

manufacturing base in the country, it stands a good chance

to qualify even for providing equipment to public sector

projects. Government entities, ostensibly with a view to

obviate Chinese suppliers in the tendering process, demand

that suppliers have a local manufacturing base.

JVS FOR SUPERCTIICAL EQUIPMENT |

| Name of JV |

Local Company |

Equity |

Foreign Partner |

Equity |

Location |

Equipment |

| |

|

(%) |

|

(%) |

|

|

| L&T-MHI Boilers Pvt Ltd |

Larsen & Toubro |

51 |

Mitsubishi Heavy Inds, Japan |

49 |

Gujarat |

B |

| L&T-MHI Turbine Generators Pvt Ltd |

Larsen & Toubro |

51 |

Mitsubishi Heavy Inds, Japan |

49 |

Gujarat |

TG |

| Toshiba JSW Turbine & Generator Pvt Ltd |

JSW Group |

25 |

Toshiba, Japan |

75 |

Tamil Nadu |

TG |

| Alstom Bharat Forge Ltd |

Bharat Forge |

49 |

Alstom, France |

51 |

Gujarat |

TG |

| Thermax Babcock & Wilcox Ltd |

Thermax |

51 |

Babcock & Wilcox, USA |

49 |

Maharashtra |

B |

| BGR Turbines Company (P) Ltd |

BGR Energy |

74 |

Hitachi Ltd, Japan |

26 |

Tamil Nadu |

B |

| BGR Boilers Pvt Ltd |

BGR Energy |

70 |

Hitachi Power Europe, Germany |

30 |

Tamil Nadu |

TG |

| B=Boilers, TG=Turbine-Generators |

B. LOCAL SUPPLIERS

BHEL: Bharat Heavy Electricals Ltd has been the traditional

supplier of power generation equipment to Indian power

plants. This was very much the case when power generation was solely in the hands of public sector entities. When India

embarked on its supercritical technology endeavour, it was

naturally expected BHEL would extend its role. However,

this was not to be. When NTPC embarked on two

supercritical power plants (Sipat in Chhattisgarh and Barh in

Bihar), the tendering process was put on hold for BHEL to

acquire competency and participate in the bidding process.

However, BHEL could not acquire the technology on time,

and both the projects were delayed only to be finally supplied

by international supercritical power equipment players.

In the supercritical business, 's success has been

mixed. The Central PSU engineering company has won

orders worth 10,120 mw of equipment—in most cases,

both boilers and turbine-generators. The orders have

come from both public and private sector companies.

Apart from securing orders through nomination or

through competitive bidding, the PSU engineering

company has also used the "developer" route. BHEL has

so far formed two joint ventures with state power

generation utilities to develop supercritical power

projects. While BHEL would have a minority (26 per

cent) stake in the JVs, the engineering company would

be the de facto supplier of power equipment. The two

JVs formed are with Tamil Nadu Electricity Board (now

bifurcated) and Karnataka Power Corporation. In both

the cases, the power plants will employ 800 mw-rated

supercritical units.

India's demand for power generation capacity—both

supercritical and conventional—has grown at such a

phenomenal pace that it would be physically impossible

for BHEL to match the demand. Today, BHEL is indeed

contending with an inevitably declining market share,

facing competition from domestic as well as international

players. Going forward, BHEL's success will be governed

by market forces and it faces true competition from

domestic as well as international companies.

Joint ventures: The emergence of joint ventures

between Indian and foreign companies in the power

equipment space, and more so in the supercritical arena, is a

defining moment for the Indian power sector. So far, at least

five collaborations are in play and in some cases, the partners

have even commissioned their equipment manufacturing

plants. Here is a brief note on each of the JVs.

L&T-MHI: In January 2011, Larsen & Toubro and its

joint venture partner Mitsubishi Heavy Industries

commissioned its twin manufacturing facilities for

supercritical equipment at Hazira in Gujarat. The two

facilities will produce supercritical boilers and turbinegenerators,

respectively. The indicative capacity of the

plants is 5,000 mw per year, and L&T has 51 per cent stake

in each of the ventures. L&T-MHI secured its first order

when it won the turbine-generator package of the 2x800-

mw Krishnapatnam supercritical project developed by a

joint venture between APGenco and IL&FS. Later, L&TMHI

won the BTG package for Jaypee's Nigrie project

(2x660-mw) and Mahagenco's Koradi project (3x660-mw).

L&T-MHI is also a strong contender for the NTPC's mega

tender, which has been discussed separately.

NTPC'S BULK TENDERING |

| Project |

State |

Capacity |

| |

|

(mw) |

| Mauda (Stage II) |

MAH |

2 x 660 |

| Solapur |

MAH |

2 x 660 |

| Nabinagar |

BIH |

3 x 660 |

| Meja |

UP |

2 x 660 |

| Raghunathpur (Stage II)* |

WB |

2 x 660 |

| Kudgi |

KAR |

3 x 800 |

| Darlipali |

ORI |

2 x 800 |

| Gajmara |

ORI |

2 x 800 |

| Lara |

CHH |

2 x 800 |

| Total for 9 projects |

|

14,460 |

| *For Damodar Valley Corporation |

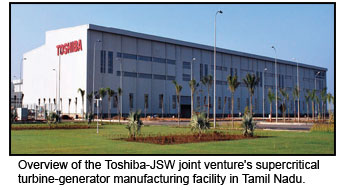

JSW-Toshiba: In February this year, the turbinegenerator

manufacturing facility of the joint venture

between JSW Energy and Toshiba Corporation of Japan

turned operational. The two partners joined forces in late

2008 to set up a $160-million facility in Tamil Nadu. The

new facility will produce high-efficiency steam turbines

and generators for supercritical thermal power plants, in

generating capacities ranging from 500 mw and 1,000 mw.

The plant's annual production capacity, currently at

around 3,000 mw, will be doubled to 6,000 mw by March

2015. It will form a major manufacturing hub serving the

global markets, alongside Toshiba's manufacturing base in

Japan, a statement from Toshiba Corporation observed.

Export destinations will include Middle East and

Southeast Asia. The joint venture Toshiba JSW Turbine &

Generator Pvt Ltd has so far won an order from NTPC to

supply three supercritical turbine-generator sets for the

Kudgi project in Karnataka.

Alstom-Bharat Forge:

Alstom-Bharat Forge: The joint venture is ready with

its manufacturing facility in Gujarat for supercritical

turbine-generators. Alstom Bharat Forge Power Ltd has

emerged as L1 for NTPC's tender for sourcing 660-mw

supercritical turbine-generators. The JV is awaiting

NTPC's final award to start production.

Thermax-Babcock: Thermax, the Pune-based

engineering company, formed a joint venture with its longstanding

partner Babcock & Wilcox of USA. Thermax

Babcock & Wilcox Ltd, in which the Indian partner holds

51 per cent stake is developing a manufacturing facility

near Pune in Maharashtra for advanced boiler systems for

supercritical plants.

BGR-Hitachi: In August 2010, Chennai-based BGR

Energy Systems formed two joint ventures with Hitachi of

Japan for manufacture of supercritical power equipment.

This marked the entry of BGR Energy, till then a leading

player in the balance-of-plant space, in the turnkey EPC

contracting for power generation plants. The first joint

venture BGR Turbines Company (P) Ltd was formed with 26

per cent holding by Hitachi Ltd. The second, for boilers,

called BGR Boilers Pvt Ltd, has Germany-based Hitachi

Power Europe GmbH as its 30-per cent equity partner. The

manufacturing facilities of both the plants are in advanced

stage of completion. BGR-Hitachi, according to reliable

estimates, is likely to get its first orders soon. NTPC is on the

verge of mandating the JV to supply four turbine-generators

of 800-mw each.

NTPC'S MEGA SUPERCRITICAL TENDER:

THE BIG PUSHNTPC is in the midst of finalizing a bulk tendering process

for supercritical power units, both of 660-mw and 800-mw.

For suppliers—both traditional and new-generation—this

represents a big business driver. NTPC is procuring as many

as 19 supercritical power units of which 11 are of 660-mw

variety and nine are of the advanced 800-mw variety. The

aggregate size of the order is 14,460 mw (See Table).

In the first round, initiated in 2010, NTPC sought 11 units

(boilers and turbine-generators) of 660-mw each. This

included nine units for its own projects and two units for

Damodar Valley Corporation. The bidding process has been

delayed as some bidders moved court following their

disqualification. The tendering routine was revived after the

Supreme Court in February this year overruled a Delhi High

Court judgement. In March 2011, the Delhi High Court had

upheld the plea of a consortium of Ansaldo and Gammon

against its disqualification by NTPC. Results of this tender

would be finalized by April end. For the boiler packages,

players in the fray include Bharat Heavy Electricals Ltd,

Larsen & Toubro (in JV with Mitsubishi), BGR Energy (in JV with Hitachi), etc. For the turbine package, applicants

include Bharat Forge-Alstom, Toshiba-JSW, BHEL, etc.

According to information available, BGR Energy Systems

has emerged L1 in the boilers component, while BHEL is a

strong contender in the turbine-generator component.

What is supercritical technology? |

The term "supercritical" refers to main steam operating

conditions, being above the critical pressure of water (221.5

bar). The significance of the critical point lies in the difference in

density between steam and water. Above the critical pressure

there is no distinction between steam and water, i.e. above 221.5

bar, water is a fluid.

In supercritical cycle, equipment is designed to operate above the

critical pressure of water. Supercritical boilers are once-through

where in the feedwater enters the economiser and flows through

one path and main steam exits the circuit. Typically current

supercritical units operate at 242 bar main steam pressure, 565ºC

main steam temperature and 593ºC reheat steam temperature.

Supercritical steam conditions improve the turbine cycle heat

rate significantly over subcritical steam conditions. Overall

supercritical power plant efficiency of around 42% is achievable

with current supercritical parameters. Improved heat rate results

in a 5 per cent reduction in fuel consumption, leading to a 5 per

cent reduction in CO2 emissions per MWh energy output.

(Source: Larsen & Toubro)

|

NTPC is also likely to soon finalize contracts for nine

supercritical power units of 800-mw each. These nine units

are to be deployed at Kudgi (Karnataka), Darlipali and

Gajmara (both Orissa) and Lara (Chhattisgarh). Speaking to

Electrical Monitor, a senior official from NTPC said that while

some contracts have been finalized, some are held up due to

land-related issues. He explained that since the contracts are

for supply and erection of equipment, they can be finalized

only when there is sufficient progress on land acquisition at

the project sites. While the contract for the Kudgi project has

been finalized, land-related hurdles are delaying award of

contracts for the Darlipali and Lara projects.

The NTPC official elaborated that for the 3x800-mw

Kudgi project, Toshiba-JSW Turbine Generators Pvt Ltd

has been selected to supply turbine-generators, while

boilers will be supplied by Doosan of Korea. The boiler

order will be executed by Doosan Chennai Works, the

Korean company's local manufacturing unit. It is reliably

learnt that BGR Energy Systems Ltd, which has formed

joint ventures with Hitachi Power GmbH will be

supplying four turbine-generator units of 800-mw each, to

be deployed at the Darlipali and Lara sites. Doosan will

also receive the mandate for two more boilers. Bharat

Heavy Electricals, according to reliable sources, will be

entitled to supply four boiler sets and two TG sets. The JV

between Larsen & Toubro and Mitsubishi Heavy

Industries is also expected to land orders to supply 800-

mw rating boilers and turbine-generators.

SUPERCRITICAL UNITS COMMISSIONED

Power plants based on supercritical technology are today a

reality in India. So far, three power producers have

commissioned supercritical power units. The credit for

commissioning India's first power plant with supercritical

technology goes to the Adani Group. In December 2010, the

private business group commissioned the first unit of 660-mw of its Mundra power project (Phase 2) in Gujarat. The unit was

commissioned in a record time of 36 months from zero date.

In June 2011, NTPC brought online the first 660-mw

unit of its Sipat (Phase 1) power project in Chhattisgarh. It

was widely believed that NTPC's Sipat project would be

India's first power project on supercritical parameters.

Although the contract was placed way back in April 2004,

there was inordinate delay on part of the Russian

contractors and suppliers.

Adani and NTPC subsequently commissioned

more units of their respective projects. (See Table)

Tata Power takes credit for commissioning India's

largest power unit when the first unit of the 5x800-mw

Mundra UMPP being developed in Gujarat by

special purpose vehicle Coastal Gujarat Power Ltd was

brought online.

CLP India also commissioned the first unit of its 2x660-

mw Jhajjar supercritical power project in January this year.

The unit began commercial production in March. This

project, incidentally, is the first power generation project

awarded on tariff-based competitive bidding.

As of March 23, 2012, India had at least seven

supercritical power units aggregating 4,760 mw in

operation. The achievement has been a collective effort of

Chinese, Russian, Japanese and Korean suppliers. All said,

India still awaits supercritical power plants equipped units

with domestic equipment.

It may be mentioned that there were unconfirmed

reports of three more units of 660-mw supercritical power

units commissioned by Adani Power—one unit at Mundra

and two at its Tirora plant in Maharashtra. Details could

not be confirmed till the time of writing.

OUTLOOK

The outlook for supercritical power equipment is

cautiously optimistic. The optimism emanates from the

sheer fact that India would be very inclined to use

supercritical technology in its future coal-fired plants.

Despite all its efforts to promote clean energy sources, coalfired

power plants will continue to be the mainstay for

meeting base load. Supercritical power plants therefore

offer an avenue to at least mitigate some of the environment-related adversities associated with

conventional (subcritical) power plants.

Supercritical Units Commissioned* |

| Developer |

Month |

Project |

Capacity |

| |

|

|

(mw) |

| Adani Power |

Dec-10 |

Mundra (Unit-5), GUJ |

660 |

| NTPC |

Jun-11 |

Sipat (Phase-1, Unit-1), CHH |

660 |

| Adani Power |

Jul-11 |

Mundra (Unit-6), GUJ |

660 |

| NTPC |

Nov-11 |

Sipat (Phase-1, Unit-2), CHH |

660 |

| Adani Power |

Nov-12 |

Mundra (Unit-7), GUJ |

660 |

| CLP India |

Jan-12 |

Jhajjar (Unit-1), HAR |

660 |

| Tata Power |

Mar-12 |

Mundra UMPP (Unit-1), GUJ |

800 |

| Total for seven units |

4,760 |

| *As of March 23, 2012; List may not be exhaustive |

Power producers,both private and government-owned,

are increasingly opting for supercritical power plants.

Apart from being environment-positive, supercritical

power plants are of large unit-sizes (660 mw, 800 mw, etc)

thereby offering economies of scale. Industry experts feel

that large unit-size power plants also less land-centric,

which means that they take up less land per mw than

conventional (lower unit-size) plants.

The caution in the optimism comes from the fact that

India is yet to have a track record for supercritical power

plants for domestic conditions. Although supercritical

power plants have been in operation worldwide even for

decades, experts point out to the fact that Indian coal,

though available in abundance, is of inferior quality. For

supercritical power plants to work at optimum levels, the

coal used should be of the imported grade. Although many

supercritical power plants, such as the coastally-located

UMPPs, will be fired with imported coal, there are

concerns surrounding availability of imported coal at

competitive prices.

It is estimated that 60 per cent of the total thermal power

capacity to be added in the XII Plan period (FY13 to FY17)

will be through supercritical technology. In the XIII Plan

period (FY18 to FY22), the entire envisaged thermal power

capacity addition will be through supercritical plants.

With respect to its supercritical ambitions, India appears to

be on track.

Data compiled by Electrical Monitor reveals that orders

worth around 45,000 mw have been placed for supercritical

power equipment. Another 12,000 mw or so is expected

from the mega NTPC tender that is scheduled to be

finalized by the first quarter of FY13. With this, the targets

for the XII Plan period seem attainable.

The ensuing financial year, 2012-13, will be a

determinant of sorts for the supercritical power

equipment industry. This is for several reasons. Firstly,

supplies from local manufacturers are expected to begin.

Till now, all the equipment commissioned is from

foreign suppliers. Local suppliers would include the

several partnerships between Indian and foreign

companies, discussed earlier. Even Bharat Heavy

Electricals Ltd, with several orders under its belt, is also

expected to begin its supplies during FY13. In the next 1-

2 years, the 4,000-mw of supercritical power plants

already commissioned will be in regular operation. This

will form the foundation of India's experience with

running supercritical power plants.

Amidst the overall excitement in ushering the

supercritical technology era, there are genuine concerns

regarding surplus capacity. Going by the upcoming jointventure

manufacturing plants, new capacity of at least

20,000 mw is under creation. This does not include

Chinese suppliers. In the medium term, India's demand for

supercritical power equipment, as estimated by Electrical

Monitor, would be in the range of 13,000 mw to 15,000 mw

per year. Hence, there is a possibility of excess supply,

possibly leading to competitive pricing. This is already

evident in the mega tender of NTPC where rates quoted by

Indian suppliers have been significantly lower than those

seen in previous orders. All this bodes well for power

producers and ultimately the consumer who could

possibly look forward to lower tariffs.

In summary, India has made a good beginning in its

supercritical endeavours. The next couple of years will

determine how effectively this new culture spreads on the

power canvas.

Advanced ultra supercritical |

India has taken initial steps to build India's first coal-fired 800-mw

advanced ultra supercritical thermal power plant. A tripartite

agreement between NTPC, BHEL and Indira Gandhi Centre for

Atomic Research (IGCAR) has been signed to this effect. The plant

is expected to be operational by 2017. While BHEL would design

and manufacture the equipment, testing would be done by IGCAR.

NTPC will be the project implementing agency. R&D activities on

the new technology have already started and the equipment should

be ready in about two years hence. Advanced ultra supercritical

power plants will have even more efficiency compared with

supercritical power plants. The technology will result in around 12

per cent lower coal consumption leading to lower carbon footprint. |