— Dave Bryant, Director - Technology,

CTC Global Corporation

— Dave Bryant, Director - Technology,

CTC Global Corporation

US-based

CTC Global Corporation has developed and owns the

rights to the highly efficient ACCC (aluminium conductor composite

core) technology. Recently, CTC completed its first installation in

India in association with its Indian partner Sterlite Technologies Ltd.

In this exclusive exchange,

Dave Bryant discusses the ACCC

technology and how it fits perfectly into India's growing need for

high-efficiency power transmission lines. Bryant asserts that ACCC

technology can contribute to bring about much needed efficiency to

the Indian grid. An interview by

Venugopal Pillai.

Tell us more on Torrent's 132kV power transmission line in

Gujarat - CTC's first ACCC conductor deployment in India.

Torrent Power Ltd is one of the leading private electrical

utilities in the Indian power sector. Torrent wanted to double

the capacity of an existing 132kV transmission line between

two substations in Ahmedabad, one of the major cities in

Gujarat in the western part of India, without the need to

reinforce or modify existing lattice structures. Torrent's

selection of ACCC® over other conductor options was based on

its low energy loss feature which, according to Torrent, directly

contributes to their bottom line. Torrent has taken leadership

role in India's adoption of high capacity, high efficiency

conductors, and CTC Global believes that the important step

they have taken will add confidence in ACCC conductor

throughout India.

With the collaboration agreement with Sterlite in place and

your first project commissioned, how do you see the future for

ACCC in India?

Like many other countries worldwide, India's demand for

affordable and reliable power is important to its economic

prosperity. Earlier this year, India experienced the worst

blackout ever recorded, impacting an estimated 670 million

people. The ACCC conductor's ability to double the current

carrying capacity of an existing transmission corridor without

requiring structural modifications makes it a very costeffective

way to upgrade and stabilize the Indian power grid.

Another key advantage to the use of ACCC conductor

compared to any other conductor of the same diameter and

weight is that the ACCC conductor reduces line losses under

any load condition by 30 to 40 per cent. This substantial

reduction in line losses allows the utility to deliver more power

to its customers with less generation investment/resource.

Similarly, fuel consumption can be reduced, which in many

cases can also reduce greenhouse gas and other emissions.

We understand that government-owned power transmission

utilities can be a big business opportunity given major "reconductoring"

works always on hand. How do you view this

public sector market in India? CTC Global believes that power companies, both public and

private, have a strong appreciation for modern, cost-effective

technologies that can improve the efficiency, capacity and

reliability of their transmission assets. While it takes time for

such a large and conservative industry to fully appreciate the

attributes of any new technology, the ACCC conductor has been

extensively tested, widely deployed and proven at over 220

project sites worldwide.

For example, American Electric Power (AEP), having

completed eight ACCC installations in the last seven years,

recently signed an agreement with CTC Global to purchase

about 2,700 kilometers of ACCC conductor for a single project

in Texas (a 345kV reconductoring project that will remain

energized during the installation). CTC Global believes that as

Indian utilities gain more experience with new technologies

such as ACCC, they, like AEP, will deploy them on larger scale

projects.

CTC Global also believes that the recent blackout in India will

prompt Indian utilities to take necessary steps toward

upgrading their grid, which in many ways can be accomplished

by using ACCC. As such, CTC Global sees a paradigm shift in the

approach of the public sector market in India toward the

adoption of technologies including ACCC. A few states have

adopted it already, and a few others are in the final stages of

adoption.

Coming to the technology, can you summarize and quantify the

technical advantages of ACCC over conventional conductors

like ACSR, HTLS, etc?

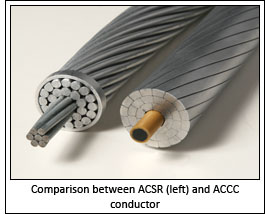

ACSR is a conductor that consists of a number of steel core

strands surrounded by conductive aluminum strands. The steel

strands are used to improve the conductor's overall strength.

There are also a variety of other conventional conductor types

that rely on higher strength aluminum alloys to increase overall

conductor strength, but the conductivity and efficiency of the

alloy typically decreases as their strengths increase.

High-Temperature Low-Sag (HTLS) conductors such as

ACSS, ACCR, INVAR, GAP and others offer increased operating

temperatures and reduced thermal sag. Unfortunately, line

losses increase exponentially at higher operating

temperatures, so, while some initial capacity increases and

cost savings may be realized, in the long term, line losses can

prove to be very costly, especially when you consider the cost

of the generation asset required to support those losses.

Internationally, it is well recognized that it is cheaper to save a

"megawatt" than it is to produce a megawatt.

At the "core" of it, is ACCC a case of carbon scoring over steel?

At the "core" of it, is ACCC a case of carbon scoring over steel?

Hybrid carbon fiber composites offer several advantages over

steel, which are well recognized in the aerospace, automotive,

marine and many other industries where efficiency,

performance and reliability are extremely important. Carbon

fiber composites offer increased strength, lighter weight,

corrosion resistance, a very low coefficient of thermal

expansion, and, most importantly, excellent resistance to cyclic

load fatigue. All of these attributes and others help elevate the

performance of the ACCC conductor above any other conductor

type of the same diameter and weight.

The ACCC conductor's greater strength, dimensional

stability and excellent self-damping characteristics allow it to

accommodate greater spans between fewer and/or shorter

structures which can serve to reduce up-front capital costs and

construction challenges on new lines. The ACCC conductor's

added aluminum content compared to other conductors of the

same diameter and weight helps increase capacity and reduce

line losses.

We hear of a new-age conductor AAAC being used extensively

in Europe. How does ACCC compare?

All Aluminum Alloy Conductors are not new, but because they

don't use a steel core, they, like ACCC, are less prone to

corrosion. Generally speaking, AAAC coefficients of thermal

expansion, operating temperature ranges and strength

limitations restrict the applications for which they can be

considered. That said, like many of the modern conductors,

AAAC can outperform ACSR conductor in many cases. To truly

evaluate the benefits between any two conductors for a specific project, CTC Global has developed the CCPTM software

program (offered at no charge) that can allow a system planner

or a line engineer to compare the electrical, mechanical and

financial impact of almost any conductor.

Tell us how has been the growth of ACCC globally since its

launch in 2005. Which countries are currently your biggest

markets?

According to Electric Power Research Institute (US) data, the

ACCC conductor has been more widely deployed compared to

any other newly developed conductor on the market today in

the same time period. To date, CTC Global has delivered more

than 14,000 km of conductor to over 220 project sites in 24

countries.

How do you view the market in India vis-à-vis other emerging

economies, mainly China? Is China home to any of CTC's ten

manufacturing partners?

China and India both represent substantial markets for ACCC

conductor due to the growing demand for affordable power.

CTC Global currently has two licensed stranding partners in

China.

India's power transmission ambitions currently involve highvoltage

technology like HVDC, UHVAC, etc. How does ACCC fit

into this scheme?

The ACCC conductor was initially developed to increase the

capacity of thermally constrained transmission lines typically

operating at or under 400kV due to the conductor's superior

resistance to thermal sag. However, its high strength, light

weight, improved efficiency and resistance to cyclic load

fatigue also make it ideally suited for higher voltage

applications where upfront capital costs, life cycle costs and

reliability are paramount concerns.

Kindly summarize CTC's way forward in India in the medium term.

CTC Global is making great strides in India to learn the needs of

the utilities and better understand how the ACCC conductor

technology can help them improve the efficiency, capacity and

reliability of their grid, which is currently plagued with a high

amount of power loss. While a number of other alternatives are

available, the utilities that are learning about ACCC and gaining

confidence in its measured performance are realizing that its

economics are hard to beat. CTC Global will continue to share

its expertise and develop strong relationships with the Indian

utilities and others worldwide. CTC Global also plans to serve

the Indian utilities by providing them with the most economical

solution to upgrade their grid and reduce overload. To support

this objective, CTC Global has also published an Engineering

Manual and developed a software program (CCP™) that it

offers to utility personnel and transmission engineers at no

charge. In addition to engineering support, CTC Global

provides installation training and other services.